|

In Spartanburg Munich, robots and people work side by side to build BMW products. The BMW Group in Spartanburg is the first production facility worldwide to succeed in the cooperation between humans and robots. There are in total four robots that construct the inside of the doors of BMW X3 models. The robots often focus on the easy work that is repeated a lot and requires lots of strength, which supports the employees. Since the interaction between human and machine requires safety standards, they move slowly and work in their own defined area. The robots have sensors, which makes them stop once they sense an obstacle.

By Geoff Caddick #mce_temp_url#

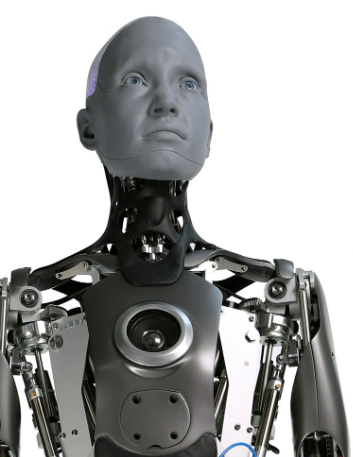

Now the BMW group is planning to use human-like robots at their flagship assemblies. The robots are made to do monotonous tasks, so the actual employees can focus on the work which can not be done by robots.

By Willy Jackson #mce_temp_url#

Other big companies like Honda, Hyundai, Tesla and Toyota are planning on using robots at the assembly line.

|